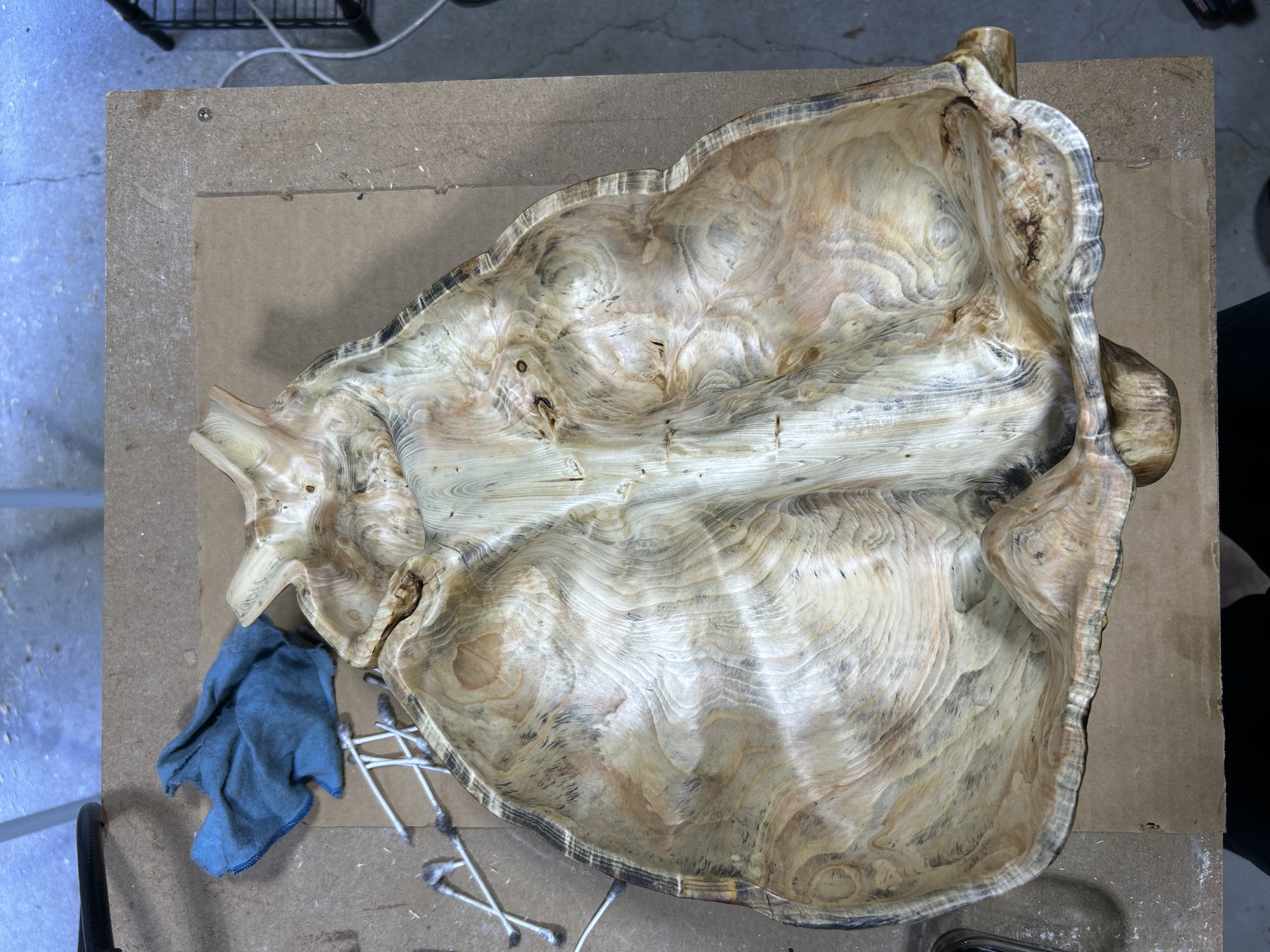

Wood Bowl

Completed 2nd half of the wood bowl heart set!

Table of Contents

Overview

- Start: Mar 27, 2021

- End: Jun 3, 2024

- Wood Species: Jack Pine

This is the other other half of the wood burl that was used for its sibling bowl. Squinting at it long enough, each bowl from this burl looks like a heart to me, so I’ve dubbed them the “heart set”. It was extracted and completed in a similar manner to that burl/bowl.

I began this project in 2021 but had to put it on the back-burner throughout graduate school, so I wasn’t able to return to it until 2023.

Bark Removal

Because I allowed the burl to dry with the bark attached, removing the bark was difficult. This was further exacerbated by the increased rugosity of this bowl compared to its sibling. I used a drill and red nylon drill brush1 to remove the easy-to-reach areas on the burl. The brush was soft enough to not damage the underlying wood. I then used a combination of a hammer/wood chisel and dremel until I had removed the bark within crevices.

Below are timelapses of the process.

Carving

Next, I needed to find a way to safely and accurately hollow the bowl.

Precise control here was critical because penetrating through the bowl edge was a non-starter.

This step was started before I departed for graduate school and finished after it.

I started with the Orbicut 40 bit2 in large areas and the Orbicut 20 bit2 in more confined areas to do large scale hollowing of the bowl.

The reader may notice that I used a smaller drill with the Orbicut 20 bit. This is because, after graduate school, I was gifted a King Arthur’s Tools Guinevere sanding system 3 which works quite well for carving with small bits.

Inner Finish Work

Sanding

Next, I moved on to sanding/polishing the inner surface of the burl, partially to even out the divots formed from the Orbicut bits' spherical shape.

I started this process by working from 80 to 320 grit using the Guinevere sanding system’s small drum sander4 5. I left a small section of the sandpaper extending past the end of the barrel so as to allow sanding in areas where the cylindrical shape was not ideal. This was necessary as I had not yet obtained the generally better option, the round sander from Guinevere6.

Fine Reshaping

There were some cracks that I wanted to make sure wouldn’t be structural issues later in the bowl’s life. I filled these with Elmer’s Woodglue7 and then sanded off any excess after letting the glue cure for 24hrs (I likely could have waited much less time).

I then rounded the edges of the bowl in an asthetic choice to soften any hard lines. I did this by hand using 320 grit sandpaper.

There were very tight, small termite holes which needed to be cleaned of debris and then sanded. I used a combination of powered and hand methods. A drill and dremel stone bit8 was used to both widen and soften the edges of the smallest holes. This was followed by hand cleaning with small picks and then finally, sanding by hand using a folded 320 grit sandpaper (folded to give rigidity).

Polishing

Lastly, I used a combination of the green (180 grit) and red (320 grit) abrasive balls9 to more finally sand all surfaces and soften any hard lines.

Cleanup

Before applying the finish coats of oil, I cleaned off any debris using a leaf-blower and vacuum (with brush-head to guard against denting the wood) on the burl. Contrary to its sibling bowl, I forwent a wet-wipe as I wanted to see the results of not raising the grain before applying the finish oil.

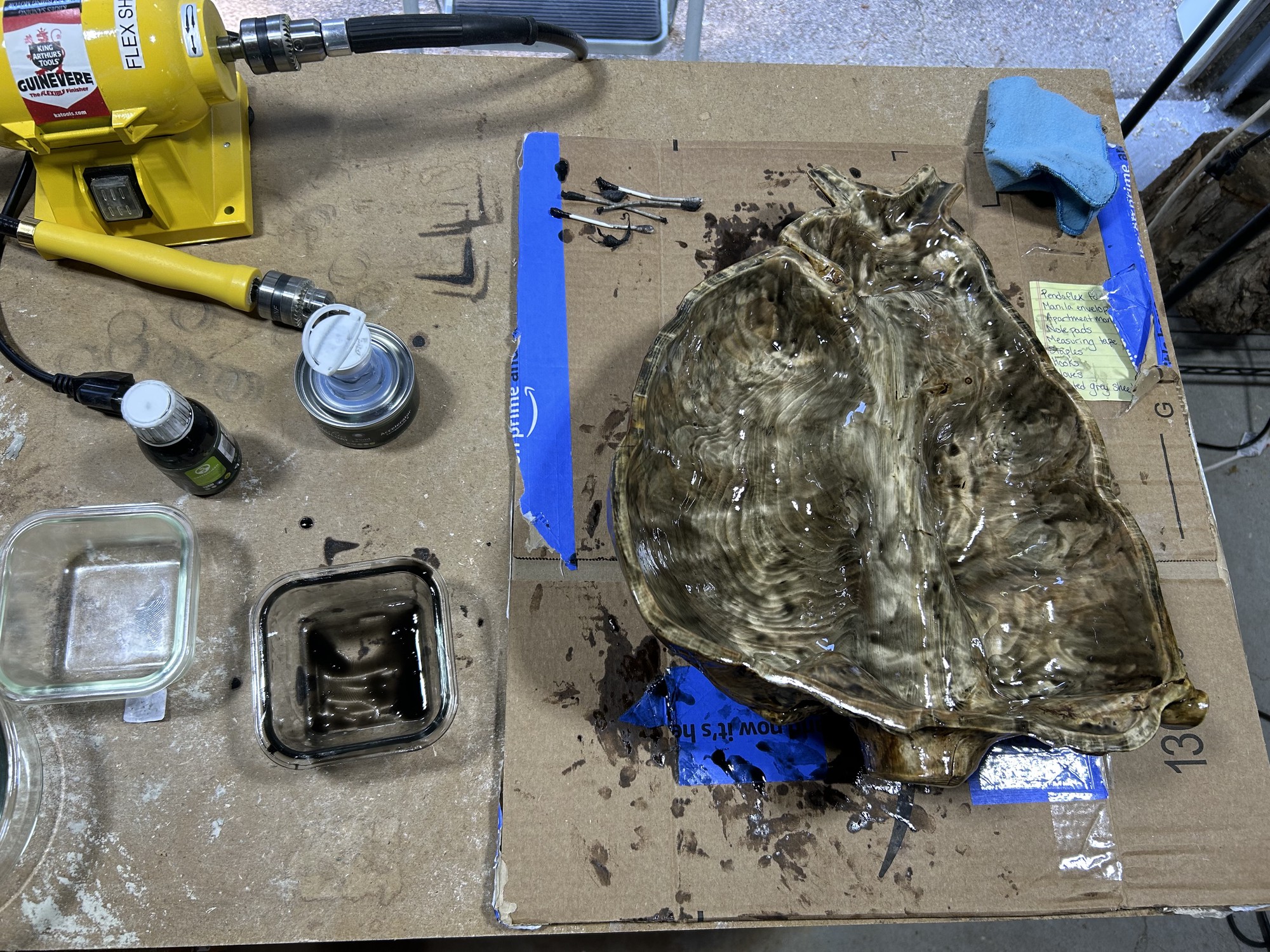

Finish Coats

The last step was to apply finish to stain and protect the bowl as well as to enhance the chatoyancy of the bowl. I wanted to match its sibling bowl’s color and finish method, so I used Walnut colored Rubio Monocoat10 following the instructions on the back of the can. I then left the bowl to dry for a week on a glass bowl to allow airflow and prevent both pooling of the oil as well as wicking of the oil into a porous material such as cardboard.

Finished Bowl

The color seems to have faded on its sibling bowl, so stay tuned for whether I try to address that.

Cheers!

-

https://www.amazon.com/Nylon-Abrasive-Wheel-Brush-Shank/dp/B07QDRCBBT ↩︎

-

https://www.amazon.com/OrbiCut-Speed-Cutting-Tool-Plano/dp/B01N5YGI35 ↩︎

-

https://katools.com/guinevere-premium-sanding-and-polishing-system ↩︎

-

https://katools.com/11367sr-guinevere-small-round-sander-replacement-bulb/ ↩︎

-

https://www.amazon.com/Elmers-E7010-Carpenters-Interior-Ounces/dp/B0045PTHH8 ↩︎

-

https://www.amazon.com/Dremel-953-Aluminium-Oxide-Grinding/dp/B00004UDIX/ref=asc_df_B00004UDIX/?tag=hyprod-20&linkCode=df0&hvadid=693524366840&hvpos=&hvnetw=g&hvrand=9564418988276556086&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9002090&hvtargid=pla-720955765674&mcid=d5d20ffbfd043daaa13f2d546d857a30&gad_source=1&th=1 ↩︎

-

https://www.amazon.com/dp/B0CQ71Y9PT/ref=sspa_dk_detail_0?psc=1&pd_rd_i=B0CQ71Y9PT&pd_rd_w=SGqsj&content-id=amzn1.sym.8c2f9165-8e93-42a1-8313-73d3809141a2&pf_rd_p=8c2f9165-8e93-42a1-8313-73d3809141a2&pf_rd_r=8GS2D0PQP0MHG6YGY8EM&pd_rd_wg=tYeG3&pd_rd_r=167289cb-e035-4a44-b20d-5d041cee73dd&s=industrial&sp_csd=d2lkZ2V0TmFtZT1zcF9kZXRhaWw ↩︎